Tije de Jong, Frans Goddijn and I are thinking of a small simple affordable-for-all fluid bed home roaster for coffee. The roaster is supposed to roast 200 grams of coffee and work with the Artisan roast software. Furthermore the machine is intended to have PID control and adjustable airflow. This combination of things would make it an ideal home or laboratory machine that will let you precisely execute predefined roast curves, roast different batch sizes and give consistent results. We decided to open source the design of this machine. This enables you to build this roaster yourself, contribute and help to further develop the machine.

Hardware and electronic design

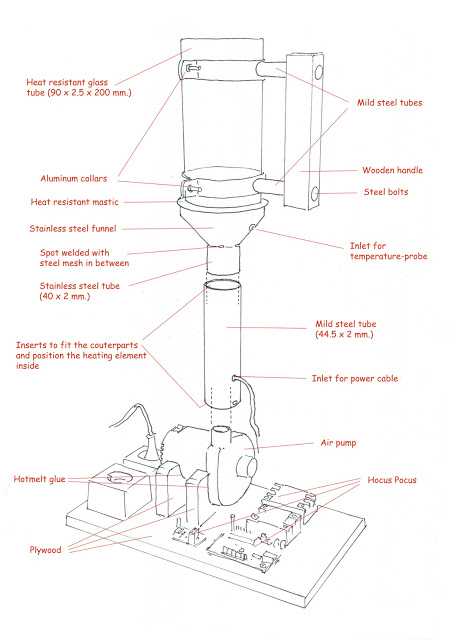

Essentially the electronics for this design consist of a heating element, air pump, two relays and a temperature probe. The hardware design is inspired by the Roastuino project. In this project they used a simple heating element (heat gun), glass roast chamber and cheap (€ 12) but effective air pump. For the ‘electronic heart’ we used TC4 Digital Thermometer and Temperature Controller. The advantage of the TC4 is that it’s relatively cheap, programmable and it already has existing firmware to make it work with the Artisan roast software. After sourcing all the hardware, Tije manufactured the remaining parts and he also constructed the prototype (see Tije’s drawing above). We used a very helpful wiring diagram (use at your own risk) that we found on the TC4 site to connect the electronics.

Firmware for the TC4

Without firmware the TC4 will not do anything. Luckily there are different firmware versions (Artisan Arduino Sketches) for the TC4 available. First we tried the latest available aArtisan that we found on this TC4 site. The code was from 2013 and we somehow did not get it to work properly. On Github we found a more recent version (aArtisanQ_PID_6_0). After compiling the Arduino sketch made by Jim Gallt we got a warning ‘Low memory available, stability problems may occur’. Maybe the code needs to be optimised, but we just hoped it’s would not be a problem.

Testing the roaster

In the video below you can see our first test of the roaster.

Last week, we tested the roaster again. The airflow and heating are nicely balanced. When using 100% power from the heating element, we were able to get 200 grams of coffee in first crack after just 4 minutes and 45 seconds. That means that the machine has lots of power. The prototype was able to communicate with the Artisan roast software. We could log the temperature and set the heating percentage. The AC fan control however didn’t work. This problem was solved by installing the newer firmware .

Testing the airflow (fan control) after software update

Logging noise

Next steps

More work needs to be done. Priorities are to configure the PID temperature control and to reduce the logging noise. Many thanks to everyone that have made this project possible. To be continued!

List of parts

Below you can see the list of the parts that we have used until now. When you add up all the costs you can see how it somehow got a little more expensive than we had hoped.

Table: List of parts

| Number | Components | Quantity | Order | Euro (ex shipping) |

| 1 | Fotek SSR 40 DA | 1 | Ebay | 4.15 |

| 2 | Crydom d2425-10 | 1 | Ebay | 25 |

| 3 | AC zero cross detector | 1 | mlgp-llc.com | 21.5 |

| 2 | TC4 SHIELD | 1 | mlgp-llc.com | 79 |

| 3 | Silverchrest Air Pump | 1 | Ebay | 12.9 |

| 4 | Ceramic Heat gun element 30 Ohm | 1 | Aliexpress? | 0 |

| 5 | Laboratory heat resistant glass (90 mm x 2.5 mm x 200 mm) | 1 | Lgsbv.com | 79 |

| 6 | Funnel (inner diameter 97mm) | 1 | ? | 7 |

| 7 | Heat resistant kit (Uni Acryl AC 180) | 1 | Kachelmaterialenshop.nl | 12.2 |

| 8 | Jumper wires | 1 | Ebay | 0 |

| 9 | Tube mounting brackets | 1 | ? | 0 |

| 10 | Wood | 1 | ? | 0 |

| 11 | K-thermocouple (miniature) | 1 | tcdirect.nl | 22 |

| 12 | 262.75 |

You can also read on Frans Goddijn’s blog about our roaster project.

Leave a Reply

You must be logged in to post a comment.